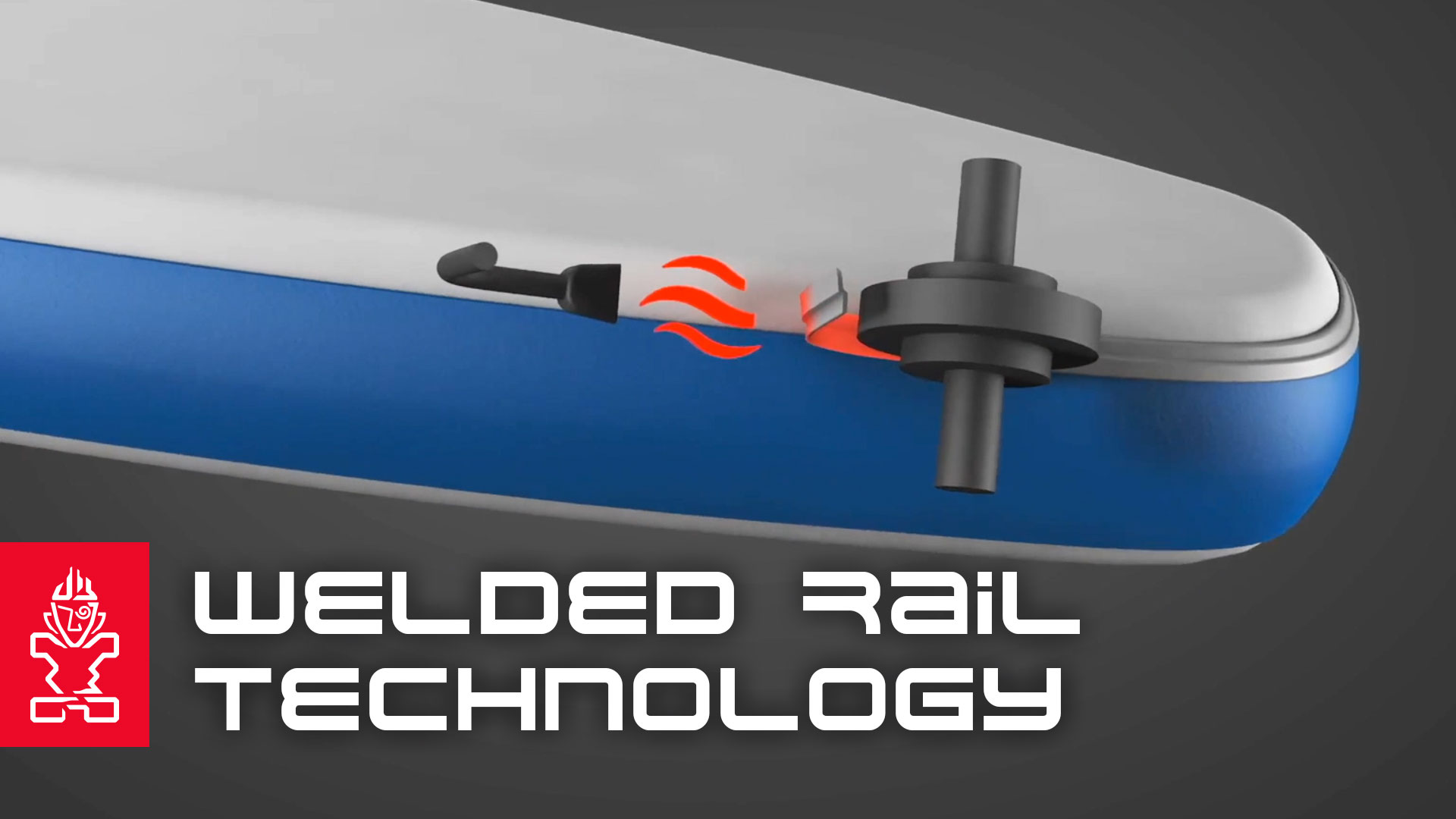

Starboard’s Welded Rail Technology – featured in our entire inflatable paddleboard range – uses a new & advanced heat-welding process whereby the top and bottom layers of the board are mechanically bonded. That means there is no glue used to join the top and bottom along the rails (where leakage can occur) and these joins are now bonded for life – making our boards the most durable on the market!

Welded Rail Technology

STRENGTH + DURABILITY

3 things you need to know about the Welded Rail Technology

- Welding the rails is the only way to avoid a board leaking over the longer term. Starboard has pioneered the most advanced and reliable rail welding technology which mechanically bonds the rail layers to the dropstitch. This makes the board more durable, longer lasting and better for the environment.

- Why are we doing it on the rails? The rails of the board are the only area where 2 main components of the board; the deck and the bottom are connected. Therefore, it’s a critical area for air leaking.

- Starboard has had a 0.38% warranty rate on all inflatable boards and a 0.1% warranty rate on Zen boards concerning leaking issues since the Welded Rail Technology was first introduced. That’s only 1 out of 1000 boards. We offer this technology on all boards produced by our new, exclusive manufacturer.

ⓘ Fusion Technology is totally different from Starboard’s Welded Rail Technology.

KEY FEATURES

NO LEAKAGE

Welded Rail technology turns 2 pieces of materials into a single solid unit resulting in an extra-strong ‘mechanical bond’.

BECAUSE RAIL IS THE CRITICAL AREA

Welded rails create a complete airtight seam without the risk of glue weakening over time.

LONG LASTING

A mechanical bond is stronger, lasts longer and better for the environment than glue.

If you want to learn even more about how Starboard developed the Welded Rail Technology and what challenges need to be overcome in the process, then read the in-depth interview with our Managing Director Joe.