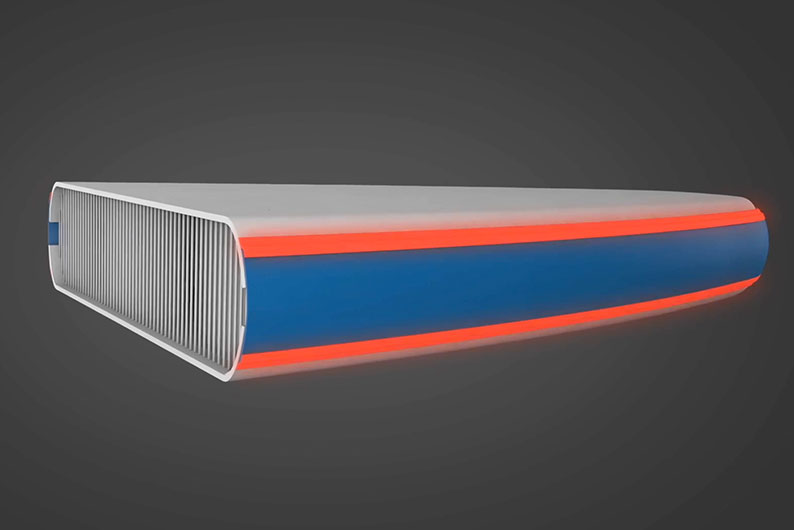

„Seit 2019 produziert Starboard alle Inflatables mit geschweißten Rails (Kanten). Das bedeutet, die verschiedenen Lagen werden mit einer neuen Technologie zu einer Lage verschweißt. Im Gegensatz zu handelsüblichen geklebten Rails sind die von Starboard deutlich langlebiger, umweltverträglicher und leichter. Geschweißte Rails sind deshalb so besonders, da es technisch sehr aufwendig ist, auch die runde Form der Bug- und Heckkante zu verarbeiten. Zusammen mit den gewebten Lagen von Deck- und Unterwasserschiff (Dropstitch) setzt Starboard hiermit die Benchmark für langlebige, formstabile und hochwertige aufblasbare SUP-Boards.“

Welded Rail Technology

HIGHLIGHTS

NO LEAKAGE

Welded Rail technology turns 2 pieces of materials into a single solid unit resulting in an extra-strong ‘mechanical b

BECAUSE RAIL IS THE CRITICAL AREA

Welded rails create a complete airtight seam without the risk of glue weakening over time.

LONG LASTING

A mechanical bond is stronger, lasts longer and better for the environment than glue.

AN INTERVIEW

An interview with Joe, Starboard Managing Director

Why did you decide to create Welded Rail Technology? What was the inspiration? Can you tell us the story of Welded Rail Tech’s origin?

It was 3 years ago when we started to see a lot of boards in the market, including our own products, start to expire and show up with problems. We felt sad for customers who purchased an inflatable board, used it little over a couple of years, but then discovered it in an unusable condition. The glue deteriorated so the board leaked or the seam opened. It was unfair on the customer who was unable to enjoy our products for a reasonable amount of time. Equally, we were alarmed that our products might end up in a landfill after just a few years. As a manufacturer we felt it was our duty to find better solution, that’s why we started this project.

What objectives and goals did you have while creating Welded Rail Technology?

Firstly, we looked at alternative glues. We went to the lab to test various types of glue. But we discovered that any glue has a limited lifespan, especially when used with PVC. We learned a lot about the parameters that affect a glue’s performance. But we also realized that glue could never be the ultimate solution due to its limitations and the way it deteriorates over time. Therefore we sought another solution that offered a proper mechanical bond to the PVC layers. That led us to welding, to give a long-lasting bond between the layers of PVC, far more durable than any glue.

Can you explain the process of developing and creating tech? How do you test welding and glue? What’s the result?

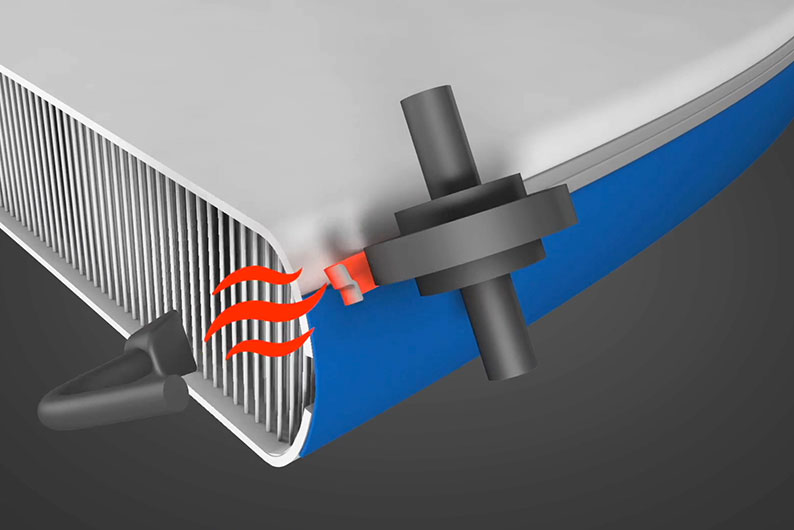

We saw that welding could be a good solution. It was already used in other PVC products like super-durable rafting boats and gigantic inflatable toys in the water park. But there were different method of welding that we needed to experiment with to understand fully. We did a lot of research. Yet we found that no one had been able to apply this technology to paddle boards. After much research and experimentation on all kinds of materials, we purchased a hot air welding machine to start the development. We had to make our own tools to overcome countless obstacles, but still failed to achieve the result we desired. Still, from all the experimentation we found that the hot air welding method provided the mechanical bonding we expected. This is the most important thing we wanted to achieve, while the other challenges are something we need to continue to work to resolve.

What challenges or problems did you face while developing welding tech? How did you solve them?

We heard that Starboard developed this tech over several years? There were many challenges during the development process. The biggest obstacle for welding drop stitch is all the hairy yarns inside the material. It made things very difficult, totally different from welding the seam of a hollow tube or rafting boat. To overcome this problem we needed to find the right tooling to handle the particular job. While experimenting with manual and handheld tools we found we were far from getting the consistency we needed. Then the challenge was to find a comprehensive machine with the tolerances we needed to get the job done. We spent months scouring the world looking for the machinery and the appropriate experience in dealing with this difficult material. In the end we had no option but to test and learn by ourselves. After we found the machine, we had to test and learn the key parameters essential for good results. With the technology it is easy to weld in straight lines, but all paddle boards have curves and corners which make things difficult. Still, we found we couldn’t have eve-thing and had to compromise. After crystalizing the concept we arrived at a middle ground where we had welding but found we could still use glue for the best cosmetic appearance of the products. It took a lot of trial and error to reach the result we were happy with. When we introduced the idea of welding the seams our factory declined, saying they had tried and failed before. After we showed them a finished sample they were still skeptical, so we invited the factory owner and chief engineer to Thailand to show them the process. When we proved it could be done we worked with the factory to fine tune the process to make it practical for production.

Can you explain exactly how Welded Rail Technology works technically from the developers perspective?

Can you also explain it like you would to a child? It is very simple, the top coating of the drop stitch material is a PVC layer and this PVC layer is melting under certain temperature. To put two layers of PVC together without glue, we need to heat up the two surfaces of PVC to the melting point then press it together. After cooling down the two PVC layers will bond into one.

While you were working on Welded Rail Technology, were there any surprises that you did not expect? Did you learn anything, or have to learn anything to complete Welded Rail Technology?

During the development process everything was new to us as we had no experience of welding. Also, we could find very little help or support as most others were in the same boat. But we learned there was a solution even when everyone said it was impossible.

What do you see for Welded Rail Technology’s future? (changes or further development?)

There is still room to further develop the Welded Rail Technology. Today the technology and process give too little room for any error, so it requires an experienced welder and takes time to get a good result.