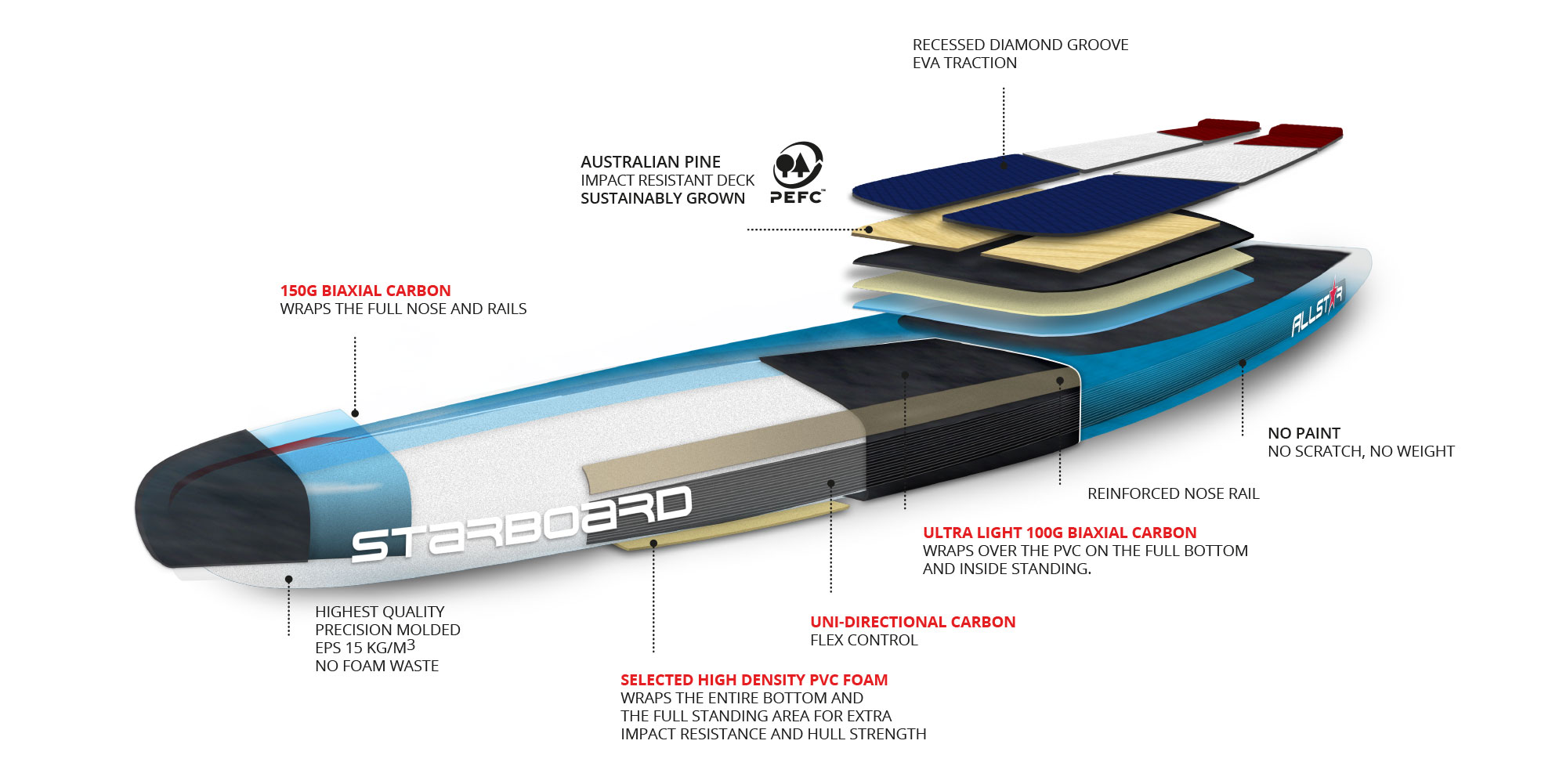

Carbon Sandwich

The Carbon Sandwich Technology is our lightest and strongest race board construction.

The Carbon Sandwich Technology we pioneered in SUP 11 years ago has been gradually improved year by year, delivering the fastest & most reactive race machines. Carbon sandwich combines the superior strength and stiffness properties of carbon fiber and PVC foam. This is our premium construction used in the world’s most successful and world-beating All Star and Sprint models.

If you require the highest performance race paddle board with no compromise, then you need to get our proprietary Carbon Sandwich Construction.

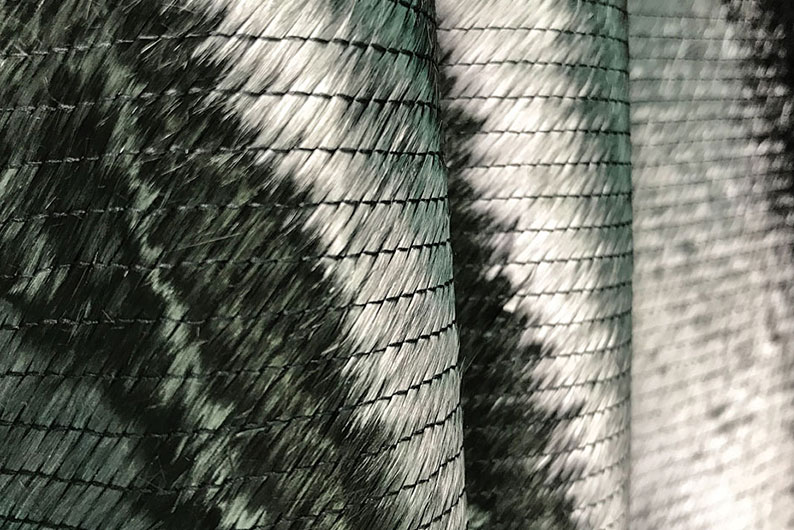

LIGHTWEIGHT BIAXIAL CARBON

• Super light-weight 100g biaxial carbon is laminated over the standing area and full bottom.

• While the stronger 150g Biaxial carbon wraps the nose and rail and the best strength ratio and efficient flex.

HIGH-DENSITY PVC

High-density PVC is used in the standing area and full bottom, reducing resin uptake and maximizing strength.

RIGID STANDING AREA

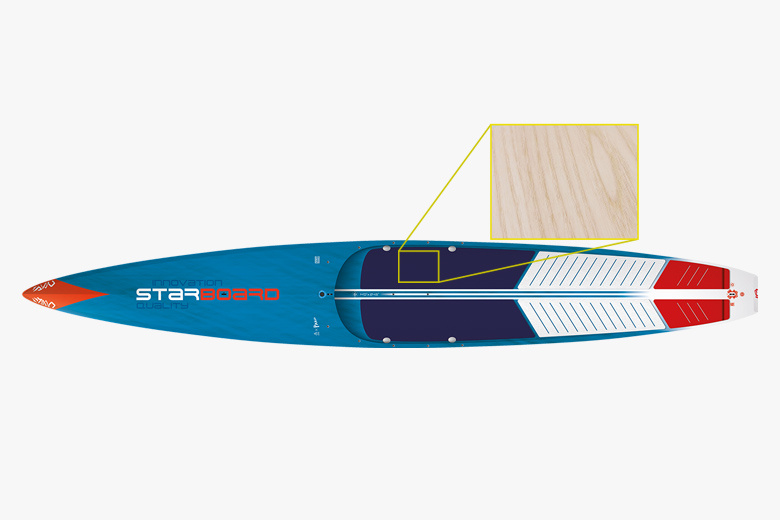

SUSTAINABLY SOURCED PINE

A standing area of 0.6mm Australian Pine is added for extra deck impact resistance and rigidity.

UNI-DIRECTIONAL CARBON

The mid-section of the board has stiffer UD carbon side stringers to maintain the rocker in the critical area, thus optimizing glide.

IMPREGNATED PAINT

NO PAINT, NO SCRATCH, NO WEIGHT

Impregnated paint pigment means no paint is sprayed, reducing the overall weight, paint chips and scratches.

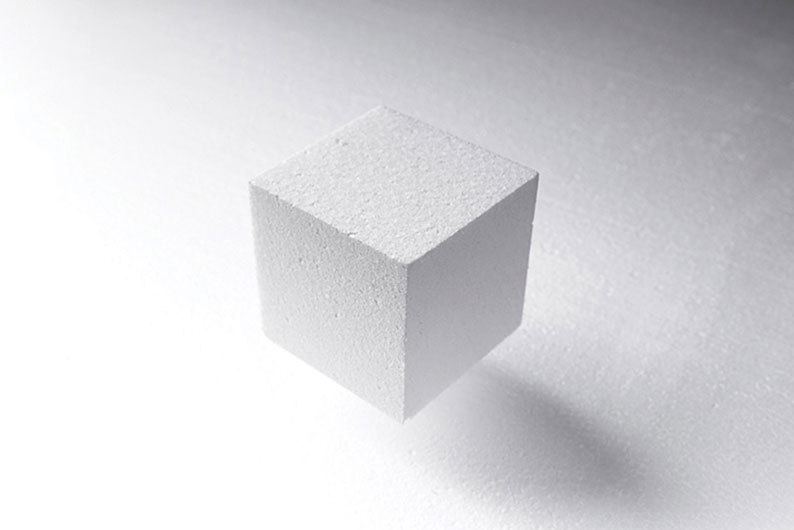

EPS CORE – 15 KG/M³ DENSITY

Shear resistant, fused and moulded individually to fit each and every Starboard board providing high strength at the lightest weight. Our moulded core technology produces zero EPS wastage.