BLUE CARBON

Extensive cost engineering, refining the layups and multiple tests has led to the 2022 Blue Carbon construction.

The Blue Carbon construction is the result of years learning how to produce the lightest and strongest constructions in both SUP & Windsurf, and refining that to come up with a new technology that delivers performance at the best value we have ever introduced in the market.

ULTRA LIGHTWEIGHT BIAXIAL CARBON

Top grade 150g Biaxial Carbon wraps the entire board, joining with an overlap on the deck and bottom to create at stringer, increasing the total breakage strength. The 45-degree woven fibre brings an ultra-crisp and responsive flex and creates the skeleton structure to strengthen the entire board.

SANDWICH TECHNOLOGY

2 skins of durable fibre glass form a sandwich around the biaxial Carbon, protecting the carbon by dampening and absorbing the impact.

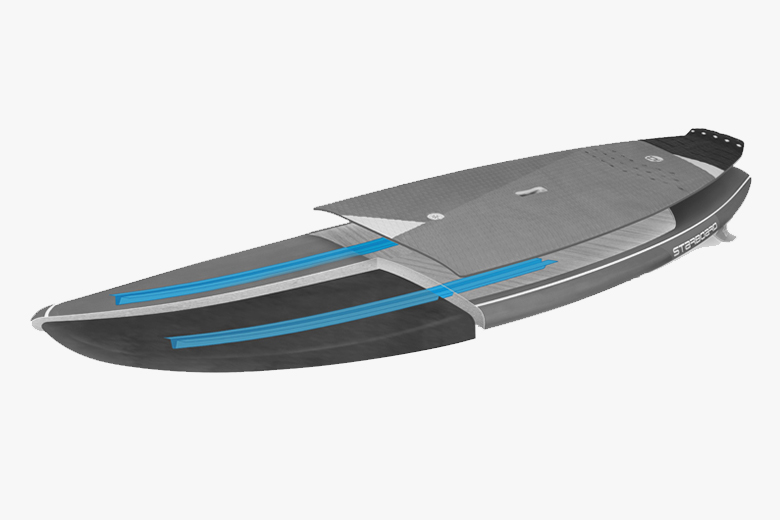

TWIN T-STRINGER DECK AND BOTTOM

PROTECTS AGAINST TOTAL BREAKAGE

The combination of twin T-stringers deck and bottom work together to increase the overall total breakage strength. The T-stringers are positioned close to the rail acting similar to an i-beam to endure heavy drops and strong wipe outs.

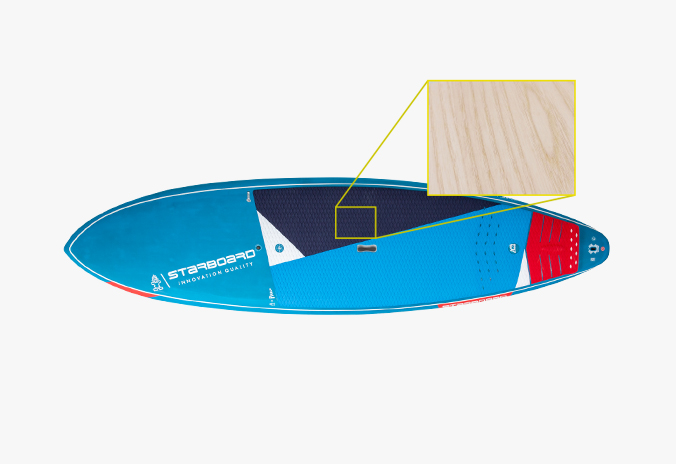

RIGID STANDING AREA

SUSTAINABLY SOURCED PINE

A standing area of 0.6mm Australian Pine is added for extra deck impact resistance and rigidity.

MULTIPLE REINFORCEMENT

In the standing area, nose and tail increase impact resistance.

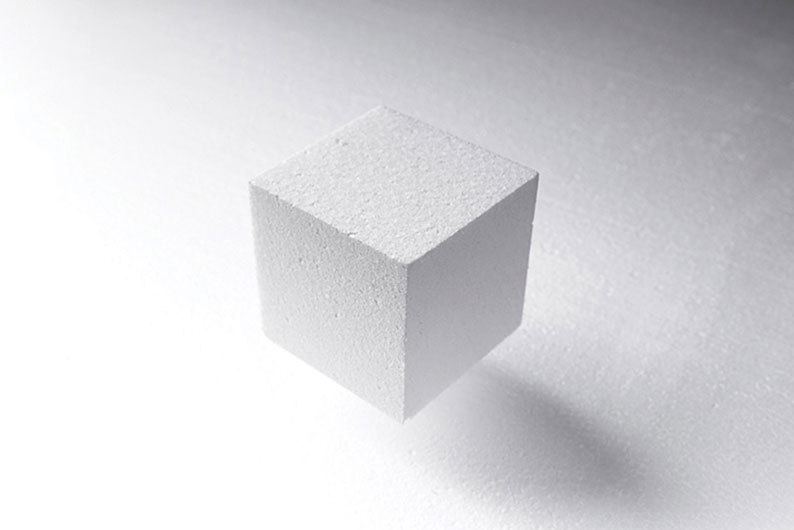

EPS CORE – 15 KG/M³ DENSITY

Shear resistant, fused and moulded individually to fit each and every Starboard board providing high strength at the lightest weight. Our moulded core technology produces zero EPS wastage.

INFUSED PAINT PIGMENT

Paint pigment is infused into the resin during lamination, resulting in a lighter weight board, elimiates paint chipping and reduces the release of harmful paint toxins.

MULTIPLE REINFORCEMENT

In the standing area, nose and tail increase impact resistance.

EPS CORE – 15 KG/M³ DENSITY

Shear resistant, fused and moulded individually to fit each and every Starboard board providing high strength at the lightest weight. Our moulded core technology produces zero EPS wastage.