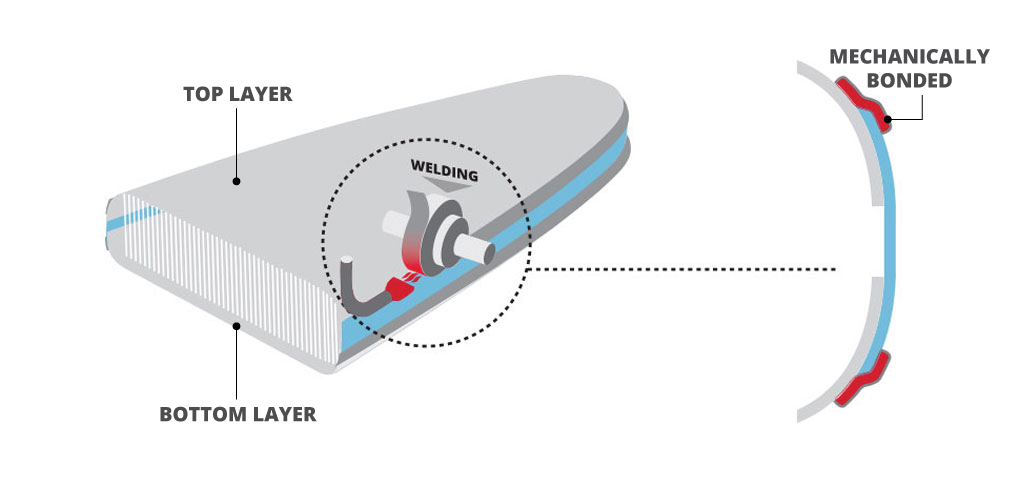

Starboard’s Welded Rail Technology – featured throughout our inflatable board ranges – uses an advanced heat-welding process whereby the top and bottom layers of the board are mechanically bonded with the rail bands. These joints are now bonded for life – making our boards the most durable ones on the market.

So Why Welded Rail Technology?

1/ No Leakage:

Welding the rails is the only way to avoid a board leaking. Starboard has pioneered the most advanced and reliable rail welding technology which mechanically bonds the rail layers to the dropstitch. This makes the board more durable, longer lasting and better for the environment.

2/ Long lasting:

Starboard has had a 0.16% warranty rate on all inflatable boards concerning leaking issues since the Welded Rail Technology was first introduced. That’s only 2 out of 1000 boards. We offer this technology on all boards produced by our exclusive manufacturer.

3/ Rails are the critical area

The rails of the board are the only area where the 2 main components of the board; the deck and the bottom are connected. Therefore, it’s a critical area for air leaking.

Where to buy

Our global dealer network can offer more information on where to buy Starboard products, pricing in your local currency or the availability of a particular model.

Please use the shop finder map above and contact your nearest shop to buy or get more info.